S355MC HOLLOW SECTIONS

YUANTAI GROUP is the largest hollow sections factory in Northern China, yearly produce 10,000,000tons hollow sections.

S355MC is a hot-rolled, high-strength low-alloy steel. It combines high strength with outstanding formability and consistent quality. It replaces conventional construction steel for applications where high strength is paramount. It is ideal for load-bearing and lifting applications including earthmoving equipment and agricultural machinery. It is also a popular choice for pressed parts including car seat components, radiators and fuel systems.

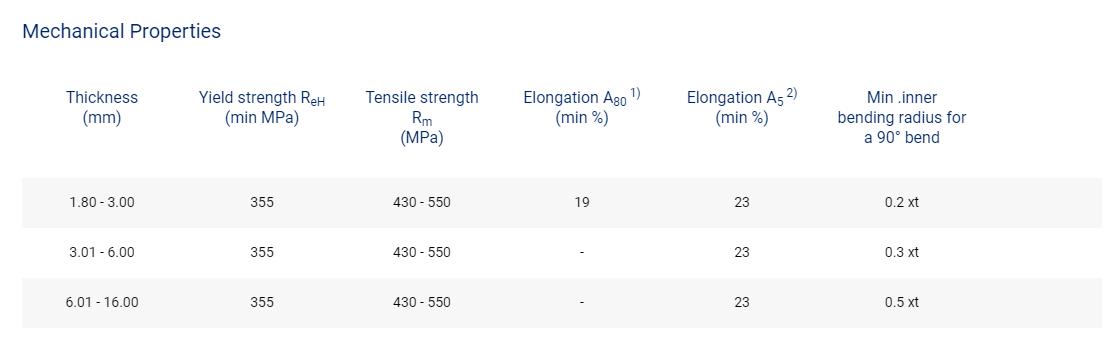

S355MC grade is produced under rigorous quality control. A well-balanced analysis with a fine grain structure produced through thermomechanical rolling creates a steel with first-class mechanical and cold-forming properties.

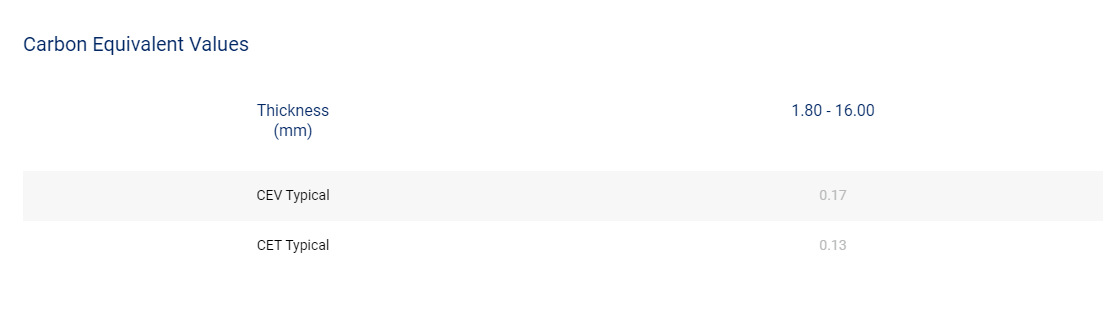

Together with the steel’s high purity, these properties make for outstanding repeatability, excellent bending and cutting characteristics and a steel that can be welded using all standard methods.

This makes 355MC the ideal choice when looking for high productivity and high-quality end products. Typical applications include a wide range of fabricated components and steel structures.

S355MC meets or exceeds the requirements of S355MC in EN 10149-2. Upon agreement, it can be delivered as double certified. This double certification will enable producers of steel structures, in accordance with EN 1090, to use S355MC in their CE-marked final component or structure.

Product Range®: S315MC, S355MC, S420MC, S460MC, S500 MC,

S550MC S650MC, E690TM, S700MC

Ympress® Laser: E250C / S355MC / S420MC

Thickness range: 1.5 - 30mm

Width range:20*20-500*500;20*30-400*600mm

Surface treatment: Hot rolled dry, pickled & oiled.